In this entry, we’ll discuss equations and variables. By using variables, you can assign a

dimension to multiple features or sketches and update them from one

location. This is much easier than

trying to remember in your model where the dimension 15mm occurs. Also, an equation in SOLIDWORKS is a very

powerful tool. You can control parts and

have them automatically update in regards to new dimensions or updated

dimensions in a design.

Segment 1 uses variables and equations throughout the

test. Before we begin the exam, let’s

turn on two features in SW that will come in handy. If we go to Tools/Options – System Options

then Feature Manager, we can set Equations and Sensors to ‘Show’. This will populate both in the design tree so

we can easily find it when we are working on our test. We will discuss Sensors later in the blog.

Now when we start a new part, in the feature tree, we can

see both of these options.

When we start our test, we see that we are given some

variables and further into the test, we are given an equation. Let’s look at how to enter these variables

and equations before we even start modeling.

We will start a new part, right click on the equations

folder and select ‘Manage Equations’. This

will open up our equations dialog box.

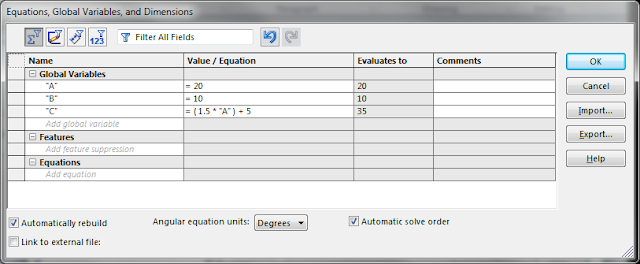

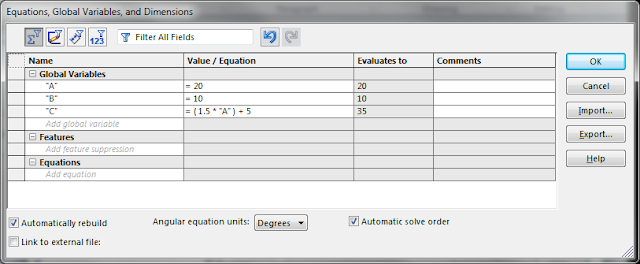

Under Global Variables, type the letter A. Tab over to Value/Equation

and give it a value of 20. Hit the Enter

Key and it takes you to the comments box.

In a real world application, you can give this variable a description so

that people after you know what it is.

For the purpose of the test, there isn’t much value in this field. If you hit Enter again, it drops you to a new

line under “A”. Now set B equal to 10

and start a third line. On the third

line, we are going to set C equal to the equation (1.5*’A’)+5. You will notice at the bottom of the equation

manager that there is an equation section.

This is for a direct application of an equation to a dimension. While it is not needed for the exam, you can

double click a dimension and apply an equation to it from directly in the

model. The equation will be displayed

here. Let’s also check the ‘Automatically

Rebuild” box. We can now click OK and

close out the equation manager dialog box.

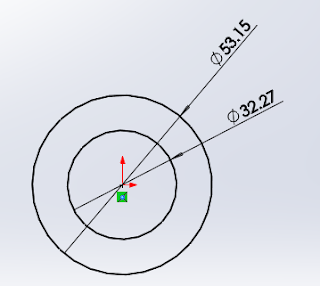

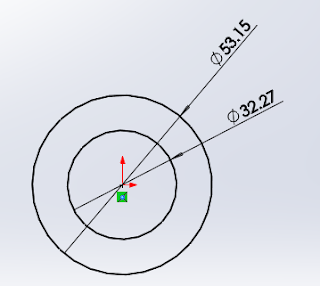

Let’s start our part on the top plane. Select this plane and start a sketch. On this plane, we will sketch two circles

with the center on the origin, one slightly bigger than the other. Put a dimension on both, the value does not

matter at this point.

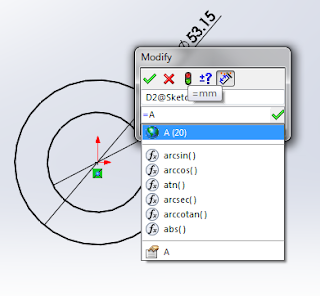

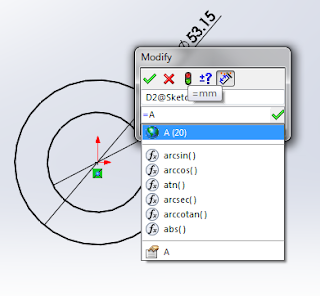

Double click the dimension for the inner circle (32.27

above). If we type =A in the dimension,

we can now link this dimension to the variable A.

Click the check and repeat the process for the second

dimension, linking it to B.

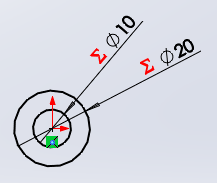

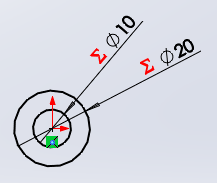

You will see that we now have our diameters linked to our

variables and SOLIDWORKS is show us a new symbol (Red Sigma) that means we are

linked to the equations manager.

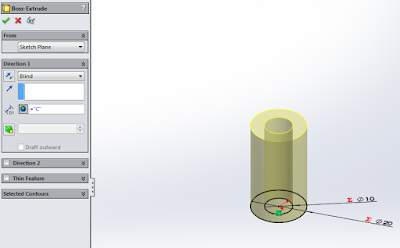

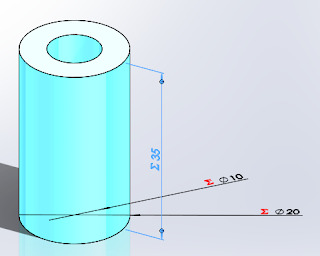

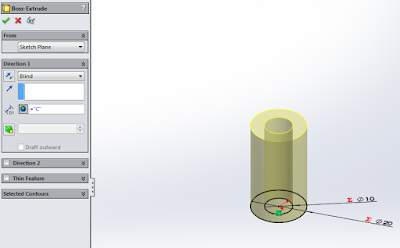

Now, let’s extrude this part. Select the Features tab, click Extrude

Boss/Base and in the Direction one boss, set D1 equal to C. Click the check mark and we have a part!

Why is this important?

On the exam, the variable will change.

The variables are also used multiple times in the exam. This is done to force you to show your

knowledge of how to use them. It’s much

easier to change A in the Equation Manager rather than sift through your models

and find every instance of A.

If we open the equations manager again by right

clicking on equations and selecting manage equations we can change these

variables. Let’s change A from 20 to

30. Move the equations manager off the

model so you can see what happens when you click ok.

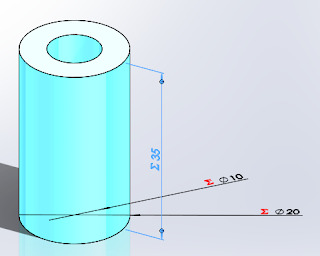

Our part changed from this:

To This:

Diameter A updated from 20 to 30 and Length C updated to

from 30 to 50.

If you have any questions on equations, post them below and

we will discuss them.

Next time we’ll talk about materials and mass.

Bryan